Contents

Sắc ký lỏng liên tục (SMB) tiết kiệm thời gian và tiền trong phòng LAB

Simulated moving bed chromatography (SMBC) is increasingly applied as a separation technique in the pharmaceutical industry, production of fine chemicals, and in the field of bioengineering.

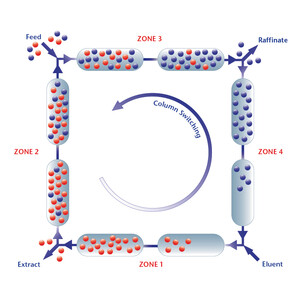

SMB is a method in process chromatography that enables substance mixtures to be continuously separated and extracted in two fractions. Its efficiency is significantly higher than batch chromatography, through better utilization of the column stationary phase.

Although in principle limited to two fraction separations, each partial fraction can be separated into further fractions by repeated use of the SMB process – down to binary substance mixtures.

Typically, the SMB process is used for two component mixtures, like chiral separations or mixtures with a “leading” or a “trailing” key product peak in the chromatogram.

Hệ thống giải pháp tinh chế với SMB

The AZURA Lab SMB System is optimized for the multicolumn separation of binary mixtures of small or biomolecules in gram-scale. The SMB System A29100 is the standard configuration of our AZURA Lab SMB. It consists of seven 8-multiposition valves and four AZURA P 4.1S included in four Assitants ASM 2.2L. The high pressure range and the biocompatibility as well as the flexibility of the multiposition valves make this system the perfect solution for SMB chromatography.

Available Upgrade-Kits

With our preconfigured Upgrade-Kits you can upgrade your SMB chromatography system very easily and build up the system you need.

System and process control: A29800 (one CORI-FLOW), A29801 (four CORI-FLOW)

Heating and column organisation: A29903 (oven), A29901 (column holder ID 50), A29902 (for columns with 8, 16 or 20mm ID)

2. HỆ THỐNG SẮC KÝ TINH CHẾ LIÊN TỤC SMB Pilot

Tinh chế liên tục trong Pilot

To extract high-purity pharmaceutical active ingredients from natural products at high yields is a major challenge. This also applies to the cannabinoid sector. Simulated Moving Bed (SMB) chromatography, as a continuous LC method, sets the standard for productivity, purity and yield.

This AZURA SMB pilot system is dedicated for the continuous production of API´s. The System allows the continuous separation of mixtures of substances and extraction into two fractions. High purities and simultaneous yields of up to 100% distinguish this process from conventional preparative LC methods.

The system features four preparative Pump 2.1L and seven multi-position valves integrated into four AZURA Assistans ASM 2.2L

- The three system pumps are equipped with 500 ml/min stainless steel pump heads, enabling volume flows of up to 250 ml/min inside the SMB cycle. The feed pump works with a 100 ml pump head and can thus also precisely dose the feed in the low flow range.

- The seven multi-position valves, operated by the valve unifier VU 4.1, are made of stainless steel and are equipped with connections for 1/8″ pipes. The Valve Unifier VU 4.1, integrated in the ASM 2.2L provides the newest technology to our SMB systems. The smart valve drive features automatic valve recognition and adjusts torque and switching speed specifically for each valve. This RFID technology enables to read GLP data, for example the maintenance of the rotor seal exchange is simplified by automatic notifications.

- The new plug-in design of the ASM 2.2L allows the modules to be removed by loosening just four screws, enabling the user to quickly exchange the modules. Especially in production processes the downtime of a system in case of service needs to be minimized.

- The PurityChrom® MCC control software provides an intuitive and easy operating of the SMB. PurityChrom® MCC offers the possibility to independently record, store, monitor, and process error messages, warnings of level meter as well as several detector signals (UV, RI), flowmeters and other signals via analog inputs. The software complies with 21 CFR Part 11.

- The Pilot SMB system includes four flowmeters. Flow rate accuracy in all SMB zones and the feed stream is recorded for each cycle. The use of four flowmeters allows a complete real-time monitoring of the entire SMB process so that the user can directly react to deviations of the flow rates.

- As a complete system, the AZURA SMB pilot system will be pre-installed on a table with the dimensions 1300 x 870 x 1000 mm (WxDxH). Every device and capillaries are fixed and therefor well structured. Additional components i.e. flowmeters are also integrable. The product streams and the column in and outlets are placed user friendly outside the table ensuring a fast and easy connection via tube fittings. The easy cleanable stainless-steel surface, antistatic wheels and leakage tubs fulfils main requirements for production areas. The AZURA SMB Pilot System can be easily transferred by the customer inside or between different production sides due to the moveable design.